WHAT WE DO

WHAT WE DO

WHAT WE DO

Pharmaceutical Development & Manufacturing Services

Pharmaceutical Development & Manufacturing Services

Pharmaceutical Development & Manufacturing Services

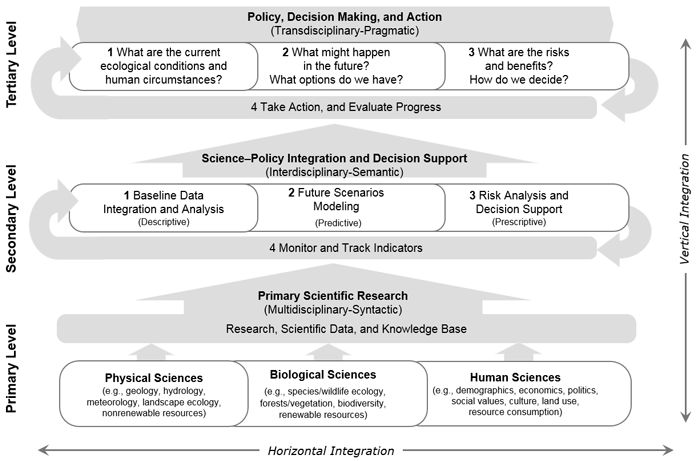

Stegram Pharmaceuticals is a leading cGMP contract service provider of integrated chemistry, drug development and manufacturing services to the pharmaceutical and biotechnology industries. We are experts in medicinal chemistry, process development and reaction optimization through to cGMP API production and sterile fill-finish services. Stegram Pharma brings more than 30 years of experience to every customer project and we emphasize quality, speed and flexibility. We can accelerate your Drug Discovery and Development Program by integrating process development, API manufacturing and finish dose manufacturing all at a single location.

We provide a full range of services from Discovery and Development to Manufacturing:

- cGMP Sterile Filling Services

- cGMP API Manufacturing Services

- API Process Development

- Formulation Development Services

- Custom Synthesis

- Flow Chemistry

- Conjugation

- Custom Peptide Synthesis

- cGMP Oligonucleotide Fill

- Contract Analytical Services

- Contract Research Services

- Medicinal Chemistry Services

- Polymorphic Screening

- Project Management

GMP Sterile Filling Services

GMP Sterile Filling Services

GMP Sterile Filling Services

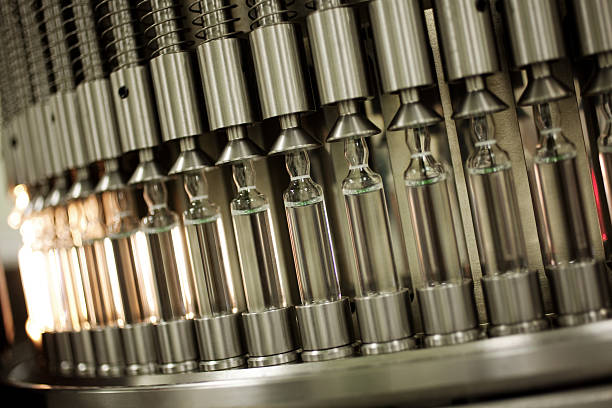

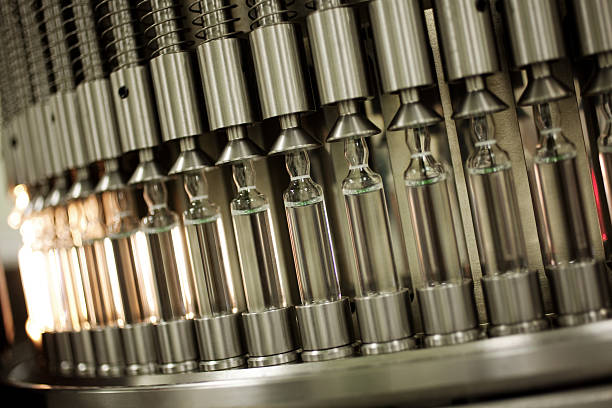

Stegram Pharmaceuticals has specialized in the development, manufacture and sterile fill/finish of pharmaceutical and biotechnology products for over 15 years. We offer aseptic filling and terminally sterilized products in a variety of finished dosage forms. Aseptic filling of sterile drugs, also known as sterile filling/finish, remains one of the most critical processes in biopharmaceutical manufacturing.

Stegram Pharmaceuticals can support your GMP sterile manufacturing and filling needs for clinical development through to small scale commercial batches. We develop and manufacture cGMP sterile products fast while meeting current regulatory quality standards. Our flexible approach and integrated offering means we make complex steriles simple. With our Steriles made Simple℠ program we can manufacture your sterile liquid in a vial for Phase I/II clinical supplies in about 4 months. We offer a selection of in-stock vial container closure options and commonly used excipients to deliver clinical materials faster, compliantlyS

We manufacture your products in our newly expanded and upgraded sterile suites which now include upgraded HEPA systems, RABS aseptic filling line enclosures, vial washing and depyrogenation as well as a new in-house WFI system which meets global sterile manufacturing standards. Our cGMP approved aseptic filling suites offer a static and operational Grade A (ISO Class 5) environment. All areas of our aseptic processing facility, including ancillary support areas, are routinely monitored for viable airborne contamination, viable contamination on surfaces and non-viable airborne contamination by our on-site QC Microbiology Laboratory. The area is fully supported by our in-house Analytical Chemistry Laboratory and Quality Assurance Departments.

Stegram Pharmaceuticals has specialized in the development, manufacture and sterile fill/finish of pharmaceutical and biotechnology products for over 15 years. We offer aseptic filling and terminally sterilized products in a variety of finished dosage forms. Aseptic filling of sterile drugs, also known as sterile filling/finish, remains one of the most critical processes in biopharmaceutical manufacturing.

Stegram Pharmaceuticals can support your GMP sterile manufacturing and filling needs for clinical development through to small scale commercial batches. We develop and manufacture cGMP sterile products fast while meeting current regulatory quality standards. Our flexible approach and integrated offering means we make complex steriles simple. With our Steriles made Simple℠ program we can manufacture your sterile liquid in a vial for Phase I/II clinical supplies in about 4 months. We offer a selection of in-stock vial container closure options and commonly used excipients to deliver clinical materials faster, compliantlyS

We manufacture your products in our newly expanded and upgraded sterile suites which now include upgraded HEPA systems, RABS aseptic filling line enclosures, vial washing and depyrogenation as well as a new in-house WFI system which meets global sterile manufacturing standards. Our cGMP approved aseptic filling suites offer a static and operational Grade A (ISO Class 5) environment. All areas of our aseptic processing facility, including ancillary support areas, are routinely monitored for viable airborne contamination, viable contamination on surfaces and non-viable airborne contamination by our on-site QC Microbiology Laboratory. The area is fully supported by our in-house Analytical Chemistry Laboratory and Quality Assurance Departments.

Lyophilization Services

Lyophilization Services

Lyophilization Services

Lyophilization also known as freeze-drying is a process of isolating a solid substance from solution by freezing the solution and evaporating under vacuum. Optimizing lyophilization cycle times and improving stability for complex injectables is a critical component of parenteral product development. The process of freeze-drying injectable drugs stabilizes compounds so they can be reconstituted just prior to administration. This process can protect biological activity, extend shelf life, and even increase dosing precision. It is also convenient for storage and transport of the product.

Stegram Pharmaceuticals Services offers cGMP aseptic formulation, fill and lyophilization services to manufacture sterile lyophilized bulk APIs as well as Drug Products in vials. We also offer QC support for your product development and manufacture. Stegram Pharmaceuticals uses its upgraded sterile filling room to aseptically fill the vials and then transfers them to our fully programmable cGMP lyophilizer. Our lyophilization batch sizes can range from 6936 vials (2 ml vial configuration) to 680 vials (20ml vial configuration) employing a Virtis 50L Ultra EL Freeze Dryer with 23 square feet of usable shelf space and 50L total condenser capacity. Click here for more information on our sterile lyophilized vials.

Lyophilization also known as freeze-drying is a process of isolating a solid substance from solution by freezing the solution and evaporating under vacuum. Optimizing lyophilization cycle times and improving stability for complex injectables is a critical component of parenteral product development. The process of freeze-drying injectable drugs stabilizes compounds so they can be reconstituted just prior to administration. This process can protect biological activity, extend shelf life, and even increase dosing precision. It is also convenient for storage and transport of the product.

Stegram Pharmaceuticals Services offers cGMP aseptic formulation, fill and lyophilization services to manufacture sterile lyophilized bulk APIs as well as Drug Products in vials. We also offer QC support for your product development and manufacture. Stegram Pharmaceuticals uses its upgraded sterile filling room to aseptically fill the vials and then transfers them to our fully programmable cGMP lyophilizer. Our lyophilization batch sizes can range from 6936 vials (2 ml vial configuration) to 680 vials (20ml vial configuration) employing a Virtis 50L Ultra EL Freeze Dryer with 23 square feet of usable shelf space and 50L total condenser capacity. Click here for more information on our sterile lyophilized vials.

Aseptic Filling in Vials – Sterile Liquid Injectables

Aseptic Filling in Vials – Sterile Liquid Injectables

Aseptic Filling in Vials – Sterile Liquid Injectables

Stegram Pharmaceuticals is a leader in the sterile cGMP manufacture of aseptically filled or terminally sterilized liquid parenteral vials. With a recently expanded and upgraded cGMP sterile facility Stegram Pharmaceuticals can meet your needs for clinical or small scale commercial products compliantly. With over 15 years of aseptic manufacturing experience, Stegram Pharmaceuticals has the experience and capabilities to meet your exacting requirements. We focus on quality, speed and flexibility as part of our integrated sterile manufacturing offering.

Our batch sizes range from small hand fills of 100’s of vials up to approximately 15,000 vials per batch. We understand the need to conserve your valuable or rare active material, whether it is a large molecule/protein or a complex small molecule. Our filling process was designed with low fill line losses in mind.

Our aseptic filling capabilities include:

- Flexicon filling line with peristaltic pump system

- Inert gas back flush capability

- RABS enclosed fill line

- Upgraded HEPA systems in suite

- New vial washing and depyrogenation services

- New WFI system

- Sterile Formulation Development Services – simple and complex

- Lyophilization services

We have validated a number of vial and stopper combinations including:

- 2 ml (Clear glass)

- 3 ml (Clear glass)

- 5 ml (Clear glass)

- 5 ml (Amber glass)

- 10 ml (Clear glass)

- 20 ml (Clear glass)

We also have standard sterile filter assembly combinations validated for sterile production. This means we can accelerate your project and minimize the validation required for your sterile project while maintaining compliance and minimizing costs. Dalton can also carry out ICH stability programs of your clinical batches to support your CMC filing requirements.

Our aseptic filling capabilities include:

- Flexicon filling line with peristaltic pump system

- Inert gas back flush capability

- RABS enclosed fill line

- Upgraded HEPA systems in suite

- New vial washing and depyrogenation services

- New WFI system

- Sterile Formulation Development Services – simple and complex

- Lyophilization services

We have validated a number of vial and stopper combinations including:

- 2 ml (Clear glass)

- 3 ml (Clear glass)

- 5 ml (Clear glass)

- 5 ml (Amber glass)

- 10 ml (Clear glass)

- 20 ml (Clear glass)

We also have standard sterile filter assembly combinations validated for sterile production. This means we can accelerate your project and minimize the validation required for your sterile project while maintaining compliance and minimizing costs. Dalton can also carry out ICH stability programs of your clinical batches to support your CMC filing requirements.

Sterile Lyophilized Vials

Sterile Lyophilized Vials

Sterile Lyophilized Vials

Need a smaller scale cGMP lyophilization services?

Stegram Pharmaceuticals offers high quality lyophilization services which include cycle optimization and cGMP production for clinical scale batches.

Our cGMP clinical scale lyophilizer can handle batch sizes aligned with your early phase clinical needs. The 0.56 m2(6.12 ft2) lyophilizer can accommodate vial sizes from 2ml to 10ml, with a capacity of approximately 1,900 vials for the 3ml format or 1,100 vials for the 5 ml format.*

Our new 18 ft2 lyophilizer on stream in 2020 will enable us to meet the demand for larger batch sizes. It will be able to accommodate from 6936 vials (2 ml format), 5,400 vials (3 ml), 3,564 vials (5ml), 2,376 vials (10ml) and 680 vials (20ml).

Stegram Pharmaceuticals uses its upgraded sterile filling room to aseptically fill the vials and then transfers them to our fully programmable cGMP lyophilizer. Our experts can aseptically fill and lyophilize your large molecule biologic or small molecule in complete compliance.

Lyophilized vials are inspected, tested and released in-house via our well-equipped analytical and microbiology laboratories. Bulk vials can be labelled with basic single color labels at Stegram Pharmaceuticals so you are ready for the clinic. Bulk material lyophilization is also available at Dalton.

* Quantities vary by vial size

Need a smaller scale cGMP lyophilization services?

Stegram Pharmaceuticals offers high quality lyophilization services which include cycle optimization and cGMP production for clinical scale batches.

Our cGMP clinical scale lyophilizer can handle batch sizes aligned with your early phase clinical needs. The 0.56 m2(6.12 ft2) lyophilizer can accommodate vial sizes from 2ml to 10ml, with a capacity of approximately 1,900 vials for the 3ml format or 1,100 vials for the 5 ml format.*

Our new 18 ft2 lyophilizer on stream in 2020 will enable us to meet the demand for larger batch sizes. It will be able to accommodate from 6936 vials (2 ml format), 5,400 vials (3 ml), 3,564 vials (5ml), 2,376 vials (10ml) and 680 vials (20ml).

Stegram Pharmaceuticals uses its upgraded sterile filling room to aseptically fill the vials and then transfers them to our fully programmable cGMP lyophilizer. Our experts can aseptically fill and lyophilize your large molecule biologic or small molecule in complete compliance.

Lyophilized vials are inspected, tested and released in-house via our well-equipped analytical and microbiology laboratories. Bulk vials can be labelled with basic single color labels at Stegram Pharmaceuticals so you are ready for the clinic. Bulk material lyophilization is also available at Dalton.

* Quantities vary by vial size

Sterile Powder Filling in Vials

Sterile Powder Filling in Vials

Sterile Powder Filling in Vials

Stegram Pharmaceuticals specializes in cGMP sterile powder filling into vials. Our unique capability allows us to fill neat sterile powders with suitable flow characteristics into vials in a Class A (100) environment. Whether you start with a sterile API or need us to perform a sterile recrystallization, Stegram Pharmaceuticals can aseptically fill your sterile powders into vials meeting USP accuracy requirements. We have filled sterile powders into a variety of vial sizes ranging from 3 ml to 20 ml, as well as into novel containers such as Hyclone PowderTainers.

For small scale sterile powder fills we use a cGMP M&O Perry LM-14 filling system capable of filling 8mg to gram quantities of sterile powders into vials. This process is suitable for clinical scale manufacturing and batch sizes up to 3,500 vials.

The speed and reproducibility of the fill is largely dependent on the flow characteristics of the sterile powder. Stegram Pharmaceuticals can run a small R&D trial to ensure your powder is ideal for this aseptic filling approach before any further investment is made.

For small to intermediate fills of powders with 100% check weight, we have a semi-automated powder filling system capable of filling from 0.1 mg up to 8 grams. This system can be used for low bioburden fills into vials which can be terminally sterilized. This equipment extends Dalton’s capability to meet the needs of our clients for powder filling. Our recently upgraded sterile processing and cGMP manufacturing suites also allow us to support your injectable drug development program using current regulatory and compliance standards.

Stegram Pharmaceuticals specializes in cGMP sterile powder filling into vials. Our unique capability allows us to fill neat sterile powders with suitable flow characteristics into vials in a Class A (100) environment. Whether you start with a sterile API or need us to perform a sterile recrystallization, Stegram Pharmaceuticals can aseptically fill your sterile powders into vials meeting USP accuracy requirements. We have filled sterile powders into a variety of vial sizes ranging from 3 ml to 20 ml, as well as into novel containers such as Hyclone PowderTainers.

For small scale sterile powder fills we use a cGMP M&O Perry LM-14 filling system capable of filling 8mg to gram quantities of sterile powders into vials. This process is suitable for clinical scale manufacturing and batch sizes up to 3,500 vials.

The speed and reproducibility of the fill is largely dependent on the flow characteristics of the sterile powder. Stegram Pharmaceuticals can run a small R&D trial to ensure your powder is ideal for this aseptic filling approach before any further investment is made.

For small to intermediate fills of powders with 100% check weight, we have a semi-automated powder filling system capable of filling from 0.1 mg up to 8 grams. This system can be used for low bioburden fills into vials which can be terminally sterilized. This equipment extends Dalton’s capability to meet the needs of our clients for powder filling. Our recently upgraded sterile processing and cGMP manufacturing suites also allow us to support your injectable drug development program using current regulatory and compliance standards.

Clinical Sterile Vial Manufacturing

Clinical Sterile Vial Manufacturing

Clinical Sterile Vial Manufacturing

Do you need your sterile injectable dosage form developed and manufactured for the clinic faster? Dalton has launched an accelerated development program utilizing its recently upgraded sterile cGMP manufacturing facilities to deliver just that.

Dalton offers a selection of in-stock vial container closure options and commonly used excipients to deliver your aseptic clinical materials faster in full compliance. We’ll take your API, develop a simple formulation and manufacture a bulk clinical liquid vial batch in about 4 months, start to finish.*

That means we save our clients time and money while getting into the clinic faster than ever. Ask us how we can accelerate your Clinical project!

What could be more Simple?

* Standard terms & conditions apply. Contact Dalton Pharma Services for more information. Integrated Drug Discovery, Development and Manufacturing

Do you need your sterile injectable dosage form developed and manufactured for the clinic faster? Dalton has launched an accelerated development program utilizing its recently upgraded sterile cGMP manufacturing facilities to deliver just that.

Dalton offers a selection of in-stock vial container closure options and commonly used excipients to deliver your aseptic clinical materials faster in full compliance. We’ll take your API, develop a simple formulation and manufacture a bulk clinical liquid vial batch in about 4 months, start to finish.*

That means we save our clients time and money while getting into the clinic faster than ever. Ask us how we can accelerate your Clinical project!

What could be more Simple?

* Standard terms & conditions apply. Contact Dalton Pharma Services for more information. Integrated Drug Discovery, Development and Manufacturing

Stegram pharmaceutical

72 high Beeches, Banstead, surrey,Sm7 1NW United Kingdom.

reach us at : [email protected]

Phone: +44(0)8712455161

72 high Beeches, Banstead, surrey,Sm7 1NW United Kingdom.

reach us at : [email protected]

Phone: +44(0)8712455161

copyright© 2022 stegrampharma.co.uk